This exhibit was unique on the show floor as it stood high above all others in every sense of the word; suspended from a massive overhead truss, its highest point it was close to 30 feet tall, 20 feet wide and 30 feet deep.

It featured six enormous suspended cubes that was 'skinned' with 48 huge 10' x 12' SEG fabric panels; four panels on the outside of each cube and four panels on the inside.

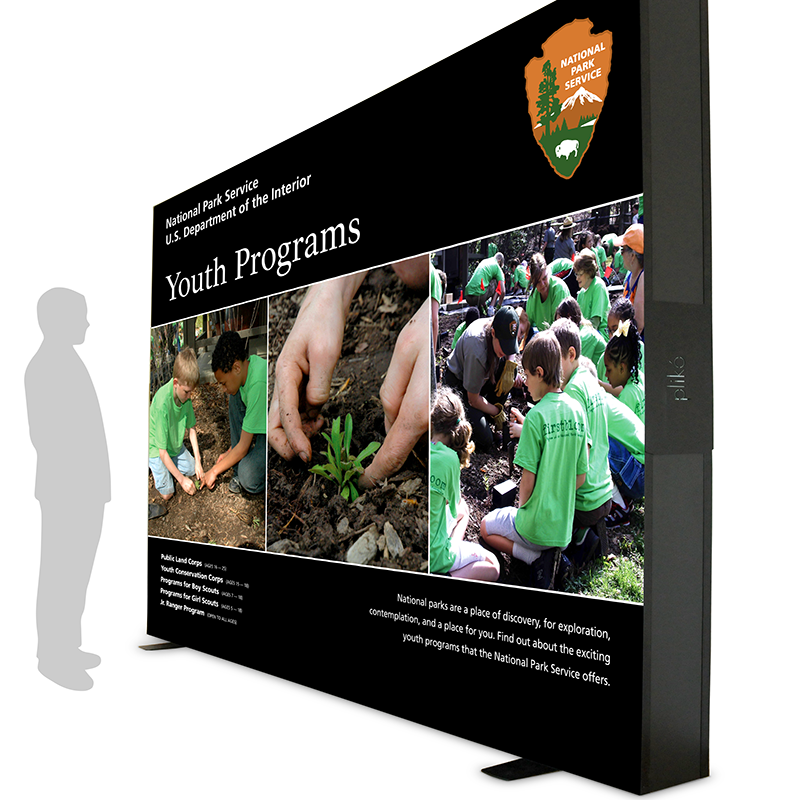

Setup of the exhibit shows the scale of the exhibit.

Exhibit Graphics featured on front page of Exhibit City News, the industry's leading trade newspaper.

Exhibit Graphics featured on front cover of Eventos Magazine.

Special Recognition:

EVENTOS TRADE MAGAZINE 2013 FRONT COVER

PROJECT: EuroShop Exhibit Design

COMPANY: AGAM Group, Ltd.

PORTFOLIO: EuroShop Exhibit Page

EXTERNAL LINK: Eventos Online Magazine

PHOTOGRAPH: Eventos Magazine

PROJECT: EuroShop Exhibit Design

COMPANY: AGAM Group, Ltd.

PORTFOLIO: EuroShop Exhibit Page

EXTERNAL LINK: Eventos Online Magazine

PHOTOGRAPH: Eventos Magazine

EXHIBIT CITY NEWS 2011 PUBLICATION FRONT PAGE

PROJECT: EuroShop Exhibit Design

COMPANY: AGAM Group, Ltd.

PORTFOLIO: EuroShop Exhibit Page

EXTERNAL LINK: Exhibit City News Online

PHOTOGRAPH: Exhibit City Newspaper

PROJECT: EuroShop Exhibit Design

COMPANY: AGAM Group, Ltd.

PORTFOLIO: EuroShop Exhibit Page

EXTERNAL LINK: Exhibit City News Online

PHOTOGRAPH: Exhibit City Newspaper

Role: Art direction, design and file production for all SEG graphics

Graphics: Primarily SEG; used over 4,000 sf of fabric

Exhibit Size: 10m wide x 6m depth x 10m height (30'w x 20'd x 30' h)

Exhibit Location: Düsseldorf, Germany

Unique Recognition: Exhibit Graphics featured on the front page of Exhibit City News, the industry's leading trade newspaper. Exhibit Graphics featured on front cover of Eventos, a Chilean trade magazine.

Graphics: Primarily SEG; used over 4,000 sf of fabric

Exhibit Size: 10m wide x 6m depth x 10m height (30'w x 20'd x 30' h)

Exhibit Location: Düsseldorf, Germany

Unique Recognition: Exhibit Graphics featured on the front page of Exhibit City News, the industry's leading trade newspaper. Exhibit Graphics featured on front cover of Eventos, a Chilean trade magazine.

About EuroShop:

EuroShop is the world's largest global retail trade fair. It is considered the gold-standard of world exhibitions and is held every three years in the town of Düsseldorf, Germany. With over 2,100 exhibitors from 50 different countries, it draws over 105,000 visitors.

For AGAM in 2011, EuroShop was the stage for the worldwide release of two new SEG fabric frame system product lines: Plikó Tool-Free SEG Display, Mizó Snap-Together SEG Display and Mizó Tool-Free Folding Counter. The entire presentation demanded an "international" look-and-feel and a visually engaging messaging that conveyed modern sophistication and elegance. I also developed the visual product identification system for both Plikó and Mizó concurrently during the exhibit design and construction.

This exhibit was unique on the show floor as it stood high above all others in every sense of the word; suspended from a massive overhead truss, its highest point it was close to 30 feet tall, 20 feet wide and 30 feet deep. It featured six enormous suspended cubes that was 'skinned' with 48 huge 10' x 12' SEG fabric panels; four panels on the outside of each cube and four panels on the inside.

In the shadows of the large six hanging cubes, the bar / storage area on the exhibit floor center featured a very unique and special optical effect. Using select SEG-compatiple extrusions and two different types of fabric - Colossus Trifab and Polylucent Polynit #9 - , a holographic effect was created by slightly off-setting visual patterns with a semi-transparent and non-transparent fabric. This holographic feel surrounded each side of the bar area.

Primary Responsibilities:

- Created the initial conception, overall art direction and design production for both the exhibit structure graphics and show floor graphics.

- Created the visual identity for the main product lines; Plikó and Mizó.

- Responsible for art directing in-house rendering staff to create all necessary oversized renders suitable for 10' x 12' large-scale output.

- Responsible for creating all large-scale print-ready artwork at 120dpi; managing over 50 gigabytes of Photoshop files for the hanging structure alone.

- Created special optical fabric effects surrounding entire bar / storage area.

- Using Dassault 3DVIA Composer, obtained measurements of all fabric areas from in-house exhibit structure staff's SolidWorks model.

- Served as the technical liaison between SEG fabric print house and in-house exhibit structure staff. This relationship allowed SEG fabric tolerances of less than 3mm between the SEG channel and graphics creating an unmatched look-and-feel of stretched fabric.

- Created the visual identity for the main product lines; Plikó and Mizó.

- Responsible for art directing in-house rendering staff to create all necessary oversized renders suitable for 10' x 12' large-scale output.

- Responsible for creating all large-scale print-ready artwork at 120dpi; managing over 50 gigabytes of Photoshop files for the hanging structure alone.

- Created special optical fabric effects surrounding entire bar / storage area.

- Using Dassault 3DVIA Composer, obtained measurements of all fabric areas from in-house exhibit structure staff's SolidWorks model.

- Served as the technical liaison between SEG fabric print house and in-house exhibit structure staff. This relationship allowed SEG fabric tolerances of less than 3mm between the SEG channel and graphics creating an unmatched look-and-feel of stretched fabric.

Secondary Responsibilities:

- Working with exhibit structure and floor graphics, provided furniture and carpet color palette recommendations based on look-and-feel of graphics.

- Worked with industrial designer and electrical specialist to "skin" overhead bar lamps with SEG fabric.

- Responsible for the design and production of aluminum name tags featuring QR code technology.

- Worked with industrial designer and electrical specialist to "skin" overhead bar lamps with SEG fabric.

- Responsible for the design and production of aluminum name tags featuring QR code technology.

Time frame:

Starting in mid-December 2010 and concluding in mid-February 2011, my aspect of the project had a ten-week window. That included initial art direction and visual style development, design / print file production, exhibit measurement, and fabric test fitting.

Starting in mid-December 2010 and concluding in mid-February 2011, my aspect of the project had a ten-week window. That included initial art direction and visual style development, design / print file production, exhibit measurement, and fabric test fitting.

Since the show was in Düsseldorf, Germany, there was no flexibility with the shipping deadline. "FedEx-ing" something last minute was not in the equation. Everything on the show floor had to accounted for, measured and test fit.

Despite the complexities of exhibiting on a different continent with different languages, procedures and labor laws, the install and take-down went perfectly.